#Regenerate

︎ Edmond Cheung, MArch 1 Student

windmill · renewable energy · plastic · recycling · vacuum forming · machine · energy brick

The programme of my project was to design a contemporary windmill at Ballyhenry Island, a tidal island located 1.5 miles north of Portaferry and East of Strangford Lough. The first practical windmill was built in Sistan, a region of Iran at least by the 9th century. The traditional from of windmill we have often seen in Europe first appeared since the twelfth century. From the 19th century, the windmill transformed from a tower alike building to a mega steel structure. Now, the mega wind turbine attached to a tall steel post becomes the signature of a windmill, and it seems that the windmills are no longer as an outcome designed by architects, but a pure machine worked with engineers. Therefore, there would be a great opportunity to re-consider the use of materials, construction methods and energy technology to re-design a contemporary windmill at the Strangford Lough from the vision of an architect.

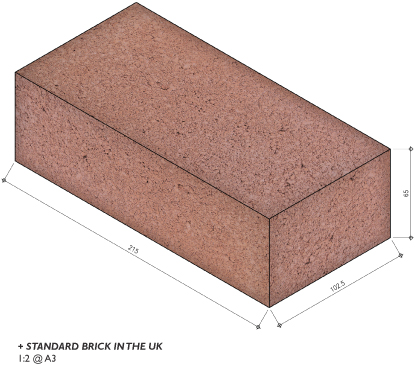

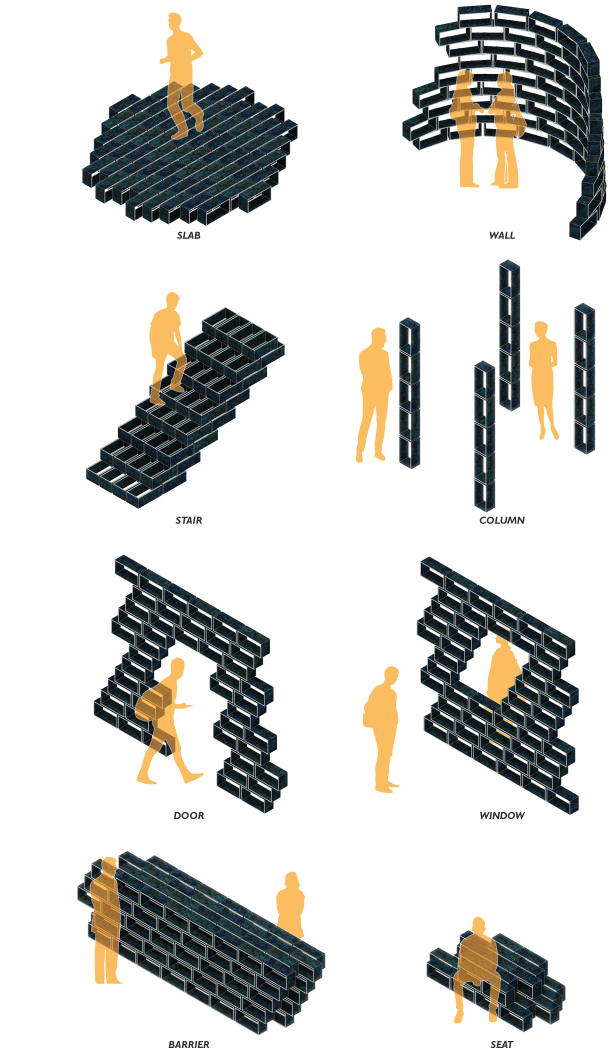

Most of the historical buildings along the Strangford Lough were built in masonry, whatever bricks or stone. The idea is to combine the technology of wind turbines and the form of bricks as a new material – “Energy Brick”. Each brick is equipped with an aluminum blade, gear set, D.C. motors and LED light bulb. When the wind flow though the energy bricks and the mini-turbines start to rotate, the energy generated from the D.C. motors will then light the LED up. The whole building can be separated into two elements: the steel hollow block and plastic “energy brick”. The steel hollow blocks are stacking together like normal brick structure and at the same time, provide structural support to the plastic “energy bricks” where they could be inserted in the steel frame as referred to the wind diagram. The steel frame also provides variations to the facade, ranging from hollow to solid plastic bricks.

In order to find out the best material and technology for the building, I have tested the making process ranging from 3D printing to vacuum forming, and different materials from concrete to polyester resin. The experiments in material and technology enriched my knowledge as an achievement in the studio.

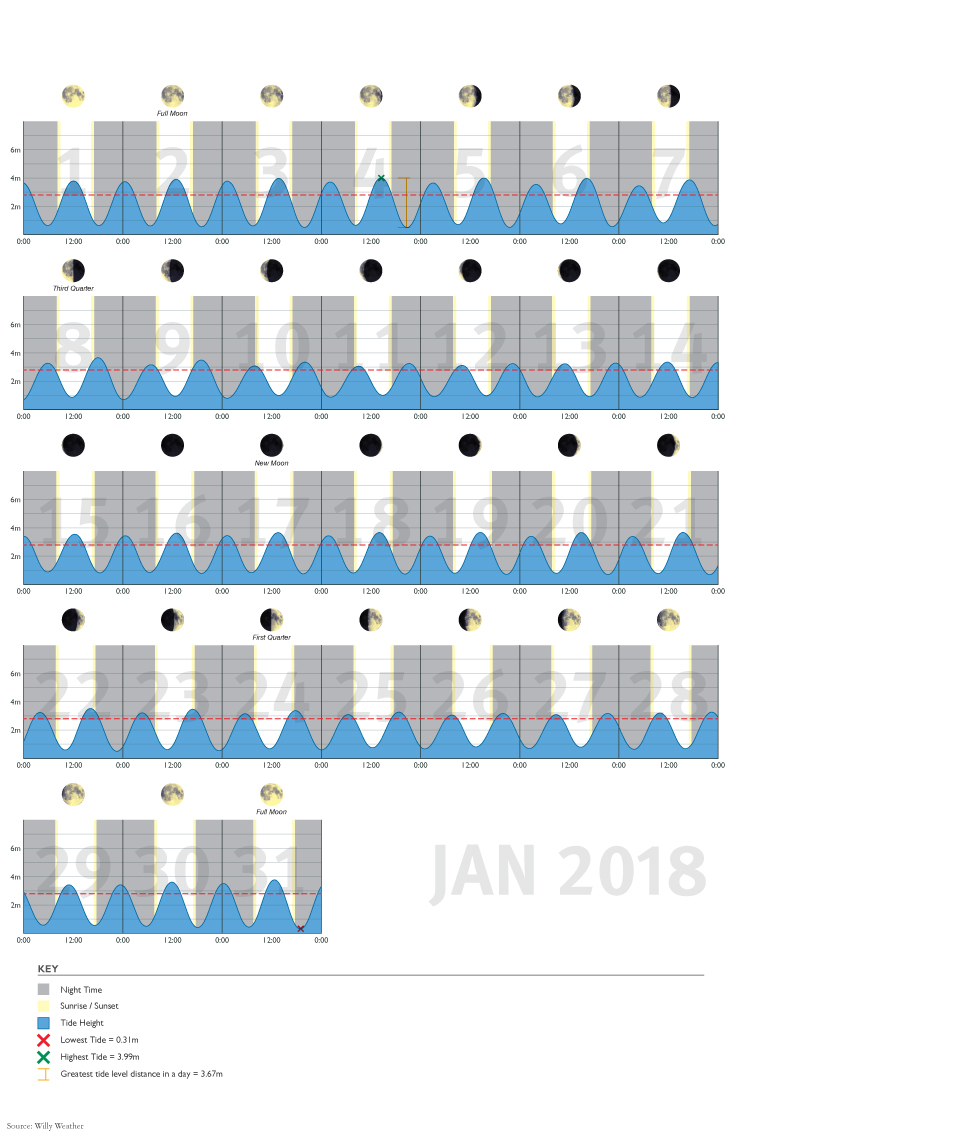

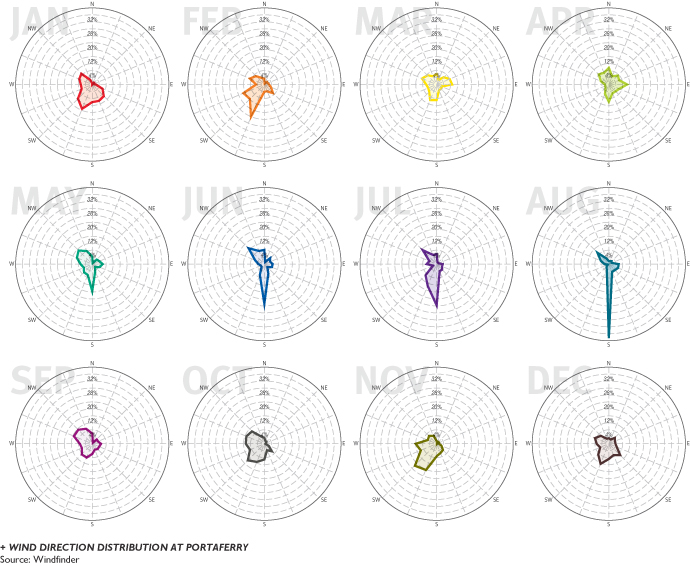

Based on the wind direction distribution diagram, most of the wind at the site was came from the south. The skin of the contemporary windmill was designed to response to the wind diagram, where more bricks with wind turbine were placed on the southern side of the windmill. The efficiency of those turbines and motors, in fact, was relatively low compared to the modern technology, but the project did not aim to generate more energy than before, but to emphasis the relation of environment to a building and investigate how the skin of an architecture could take response to the environmental changes.